Egg Carton Production Line for Paper Egg Box

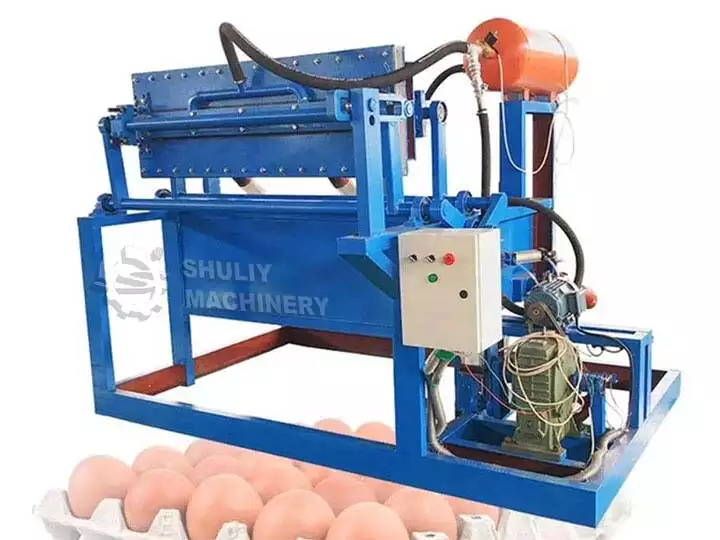

Egg Crate Machine | Egg Box Making Machine

Machine brand: Shuliy

Capacity: 1000-8000pcs/h

Final products: Egg cartons, egg crate with slid

Used equipment: Pulper, egg carton machine, dyer, hot pressing machine, baling machine

Shuliy egg carton production line is mainly used to produce various types of high-quality egg cartons/egg boxes for better storage and transportation of eggs. The egg crate machine has a capacity of 1000-8000pcs/h.

The egg carton manufacturing process includes pulping, molding, drying, hot pressing and packing.

This line can meet the needs of all types of factories and is a great choice for investors to invest in this industry. If you are interested, welcome to contact us!

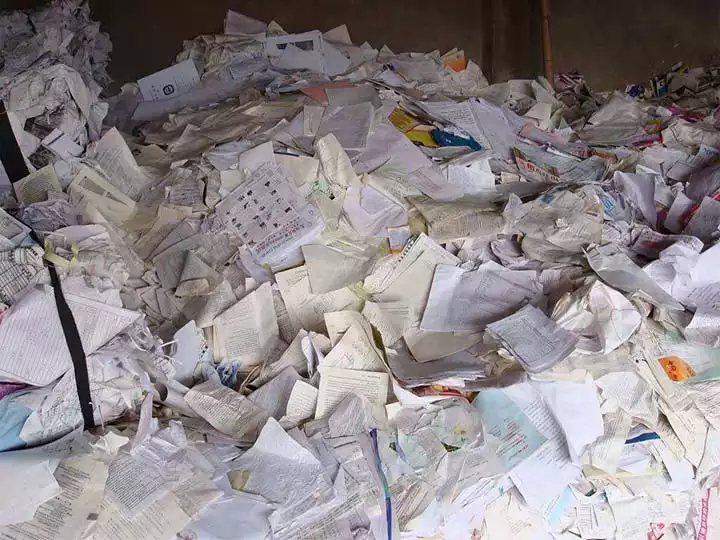

Raw materials used for egg cartons

In fact, raw materials for the production of egg cartons can be found everywhere. Not only is it very easy to obtain, but it also makes a great contribution to the environment by recycling waste resources again.

The raw materials for egg carton production include waste paper, waste books, waste magazines, and other waste materials.

Introduction of the complete egg carton production line

In Shuliy Machinery, the egg carton making machine is one of our main products. Therefore, our company’s team has researched and developed a production line suitable for different production scales.

According to the drying methods, there are three types of egg crate machine lines: manual type, semi-automatic type, and fully automatic type.

Manual egg carton manufacturing process

The manual-type production line is suitable for factories with a small production scale. The capacity of the chosen egg carton machine is not very large, so the egg carton production can be carried out smoothly using manual labor.

The production sequence is: pulp making → forming → drying → hot pressing →baling.

Pay attention to the following points:

- The drying method is natural drying. After the egg carton is produced, it is directly taken to the sun for drying, or it can be dried by using a support. But in any case, it is natural drying in the sun. This is shown in the picture.

- Because the egg carton production is carried out, the hot press is necessary. The machine functions to shape the finished product and make the finished product(egg cartons) more beautiful.

Semi-automatic egg box production line

The semi-automatic egg carton production line is proper for medium to large-scale factories. The capacity of the egg carton machine for sale is moderate, achieving semi-automation.

However, the production process is much the same as the manual one. Only the way of sun-drying is different. The semi-automatic type adopts the brick kiln drying method. So you should build the brick kiln.

Our sales staff will give you the most reasonable advice on the establishment of the brick kiln. It must satisfy your business and suit to facilitate your commercial production.

Fully automatic paper egg carton production line

The fully automatic line is applicable for medium and large-scale factories to use, especially for large-scale factories. The egg carton making machine has a large production capacity of up to 8000 pieces per hour.

The egg carton production process is the same, mainly with different drying methods.

Because it is a large-scale production, the machine is for drying the egg cartons. Thus, it realizes the automation of the whole production, greatly improves efficiency, and saves time.

How are the egg cartons manufactured?

In fact, it has a brief description in the introduction of the egg carton production line. The main process is pulp making, molding, drying, hot pressing, and baling.

These five stages correspond to different machines. Details of the egg carton manufacturing process are as below:

This pulp making machine mainly crushes the waste papers into the pulp, for the preparation for the next molding.

The paper egg crate making machine is the core part of the whole production line. It forms the quality egg carton and manufactures satisfied egg cartons.

This step is to dry the egg cartons. Because the newly manufactured egg carton is wet, drying is necessary. Three drying methods are available. Also, you can choose the suitable one based on your demands.

Because of the egg boxes, the hot pressing machine is important to shape them. After hot pressing, the egg cartons are more beautiful and attractive.

This baling machine aims to pack quality and pretty egg cartons into the stack. For the purpose of easy storage and convenient transportation, this machine is very helpful.

Advantages of the egg carton production line

- Beneficial to the environment. Because the raw materials used in the egg carton production line are waste paper, waste magazines, waste books, etc.

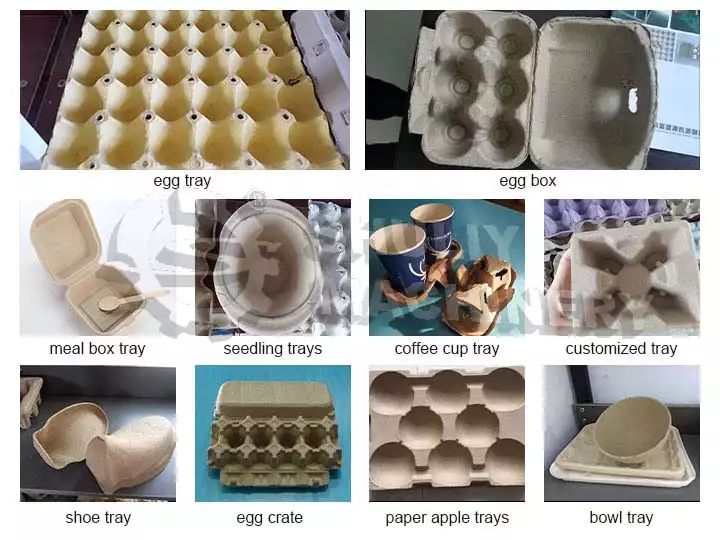

- A wide range of applications. Although it is an egg crate production line, it can also produce egg trays, shoe trays, apple trays, quail egg trays, wine trays, nursery trays, etc.

- It is easy to operate and user-friendly.

- The machines used in the production line are made of high-quality materials and have a long service life.

How much does it cost to make an egg carton?

For the automatic egg carton production line, we, Shuliy Machinery, have three types of process lines available. Therefore, there are some factors affecting the egg carton cost.

- Firstly, the raw materials. Although the raw materials are cheap and easy to get, they also have an influence on egg carton making.

- Secondly, the egg carton mold. Various molds have different prices. When used in the production line, the egg carton price differs.

- Thirdly, the egg carton manufacturers. Different manufacturers have different egg carton costs although they all produce the egg cartons. Because they use different materials and machines. If you are interested, come and get in touch with us for more details!

Shuliy Machinery – the reputable egg carton machine manufacturers

Our Shuliy machinery has the factory and our own design & research team to manufacture the most suitable and latest egg carton machine and production line. So, our machines have a competitive price.

Besides, we have the complete production line and machines. Such as the commercial egg tray production line, paper egg tray moulding machine, egg carton production line, egg carton maker, etc. You can choose what you need. Welcome to contact us at any time!

Successful case: automatic paper egg box making machine exported to Sudan

This year, a customer from Sudan approached us and said he needed to buy an egg carton machine. Because he has a chicken farm and needs to ensure the integrity of the eggs when he sells them.

After learning about our machines, he was also interested in our egg carton production line. Through communication between the two parties, he decided to buy the egg carton machine first and try it out before deciding whether to buy other machines.

After receiving the machine, the Sudanese customer liked it very much. Therefore, he bought the pulp making machine and hot press machine one after another.

Technical parameters of the egg carton machine

| Model | Capacity | Paper consumption | Water consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kW/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kwW/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kW/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kW/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kW/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kW/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kW/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kW/h | 3-4 |

Contact us now for more machine details!

Do you want to make money from the waste paper? If so, we can provide a good suggestion, use the egg crate machine to make a profit from paper tray production, if you want to know more, contact us!