1500-2000PCS/H Egg Tray Molding Machine

| Model | SL-4*1 |

| Capacity | 1500-2000pcs/h |

| Paper consumption | 160kg/h |

| Water consumption | 380kg/h |

| Energy used | 45kW/h |

| Worker | 3-4 |

You can now ask our project managers for technical details

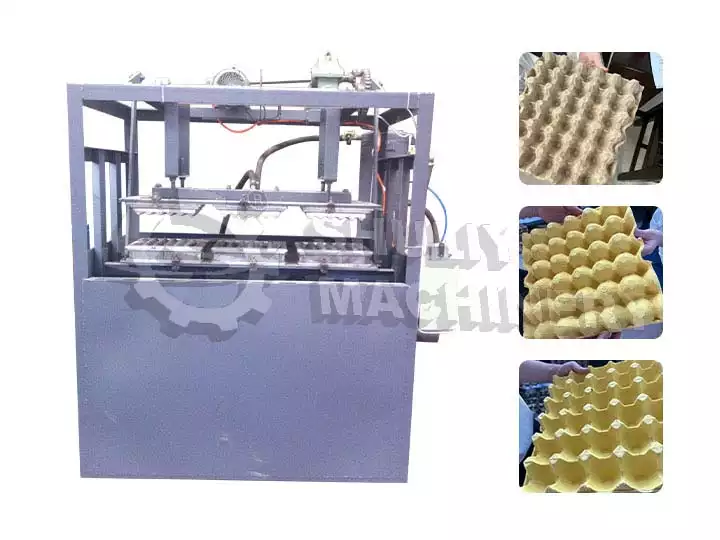

1500-2000pcs/h egg tray molding machine is especially to produce high-quality paper trays with an output of 1500-2000pcs/h from waste paper to make profits.

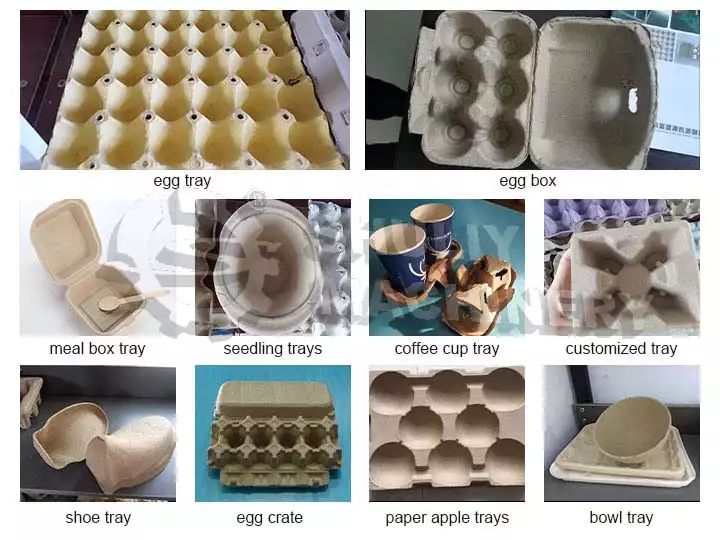

We can produce all kinds of egg trays, including egg trays, egg boxes, nursery trays, wine trays, coffee cup trays, medical trays, fruit trays, quail egg trays, and custom-made paper trays.

You can tell us what kind of trays you need, and we will customize the corresponding paper tray machine for you.

Advantages of SL-4*1 egg tray moulding machine

- Capacity of 1500-2000pcs/h: Suitable for the production needs of small and medium-sized enterprises, and effectively improves the production efficiency to meet the market demand.

- Lower investment and maintenance costs: Reduce initial investment and operating costs, providing a more cost-effective option for small and medium-sized enterprises.

- Simple design and user-friendly operation: Operate the machine proficiently after simple training.

- Versatility: In addition to producing egg trays, other paper trays can be made, such as fruit trays, wine bottle trays, etc.

Parameters of 1500-2000pcs/h egg tray molding machine

From the below table, this type of paper tray making machine has a capacity of 1500-2000pcs per hour. And the consumption of paper and water has been listed, having a certain value to show this.

Of course, our egg tray machines also have other capacities, such as 1000-1500pcs/h, our sales manager will provide the suitable one according to your needs.

| Model | SL-4*1 |

| Capacity | 1500-2000pcs/h |

| Paper consumption | 160kg/h |

| Water consumption | 380kg/h |

| Energy used | 45kW/h |

| Worker | 3-4 |

Moulds for 1500-2000pcs/h egg tray molding machine

We have both plastic and aluminum molds. And the shelf life of the molds is at least one year. Besides, our molds can also produce various types of paper trays.

As long as you need paper trays, we can customize the corresponding molds according to the paper trays, whether they are made of plastic or aluminum according to your requirements.

Drying method for Shuliy SL-4*1 Pulp molding machine

Actually, there are three ways of drying methods, respectively natural drying, brink kiln drying, and metal drying.

For a capacity of 1500-2000pcs per hour, the natural drying method is the most suitable. The reasons are as follows:

- Small scale production

- Low machine cost

- Economical and cost-effective

- Labor-saving and energy saving

Services offered for Shuliy 4*1 egg tray machine

One-to-one service

We provide customers with one-on-one service and offer the right machine based on our professional solid knowledge.

After-sales service

We provide 24-hour after-sales service to solve customers’ problems, in order to facilitate their businesses.

Customized service

We can customize the machine mould, according to the size of paper trays that you want to produce.

The successful case of Shuliy automatic egg tray molding machine

Our egg tray molding machine is always exported to foreign countries, thus, this machine has a good reputation overseas. Then list one successful case for your reference.

Contact us for more machine details!

Are you looking for a way to make money from waste paper? If yes, contact us now and we’ll provide you the best solution!