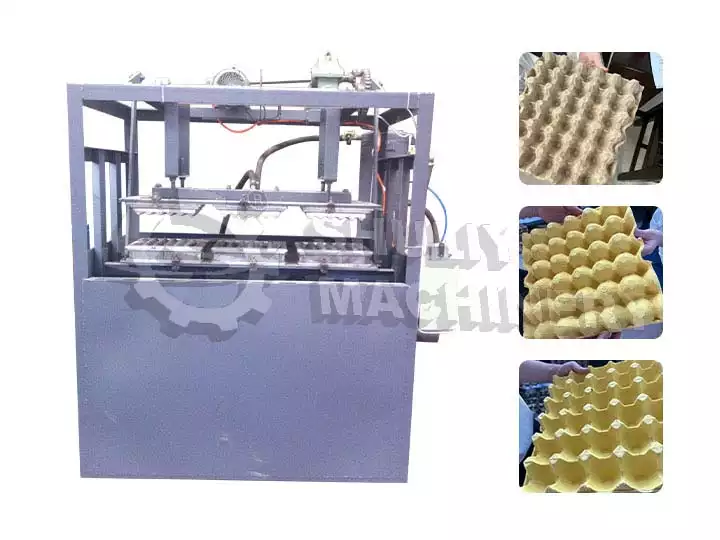

Enviar una máquina de bandeja de huevo de pulpa de papel de 1500 piezas/h a Libia

Una empresa de reciclaje en Libia planeaba comenzar un nuevo proyecto de valor agregado para estaciones de reciclaje de papel y necesitaba comprar una máquina de bandeja de huevo de pulpa de alta eficiencia.

Después de la investigación de mercado, eligieron las 1500 piezas/hora máquina de bandeja de huevos Producido por Shuliy. Sin embargo, el voltaje de la cuadrícula en Libia no coincide con el voltaje estándar de la máquina y se requiere modificación de voltaje.

Análisis de la demanda

- Demanda de equipos

- El cliente necesita una máquina que produce 1500 piezas de bandeja de huevo por hora para garantizar una alta eficiencia y estabilidad.

- Problema de voltaje

- El voltaje estándar en Libia es de 380 V/50Hz, mientras que el voltaje estándar de la máquina de bandeja de huevo de pulpa de papel Shuliy es de 220 V/50Hz, hay una pequeña diferencia.

Solución shuliy

- Modificación de adaptación de voltaje

- El equipo técnico de Shuliy ajustó el sistema eléctrico de la máquina de moldeo por la bandeja de huevos para garantizar que el equipo pueda funcionar de manera estable por debajo de 380V.

- Se agregaron reguladores de voltaje para evitar daños al equipo por fluctuaciones de voltaje.

- Optimice el motor y el módulo de control para garantizar que el equipo mantenga una operación eficiente a una frecuencia de 50Hz.

- Prueba de equipo

- Una vez completado la modificación, el equipo se probó rigurosamente en la fábrica Shuliy para simular el entorno de voltaje en Libia y garantizar un funcionamiento estable.

- Los resultados de la prueba mostraron que el equipo cumple totalmente con el requisito de producción de 1500 obleas/hora a 380 V.

- Capacitación del cliente

- Shuliy proporcionó al cliente libio de instalación de equipos y capacitación de operación (manual de operación, video, demostración de operación en línea, etc.).

- La capacitación incluyó mantenimiento diario, solución de problemas y adaptación de voltaje.

Resultados de implementación

- Operación de equipo

- La máquina de bandeja de huevo de pulpa de papel adaptada se puso en funcionamiento con éxito en la fábrica del cliente en Libia, y la eficiencia de producción cumplió con las expectativas.

- Comentarios de los clientes

- El cliente está muy satisfecho con la estabilidad del equipo y el soporte técnico de Shuliy.

- Cooperación a largo plazo

- Según esta cooperación exitosa, el cliente planea continuar comprando otros reciclaje de desechos Equipo de Shuliy en el futuro.