What is the raw material for egg tray?

In the field of poultry egg packaging, paper egg trays are gaining more and more attention and importance as an environmentally friendly and sustainable option. Paper trays are made from a variety of raw materials, including waste cardboard, newspaper, pulp, etc.

With the increasing demand for sustainable and environmentally friendly packaging, paper egg trays are an ideal alternative to traditional plastic trays. Let’s explore the raw materials used to make paper trays and their advantages, as well as how to use the egg tray machine to make them.

Raw materials for the egg tray production

The raw materials for making egg trays can be found everywhere in life, such as waste cardboard, cardboard boxes, cardboard packaging, newspapers, magazines, books, paper, etc.

Advantages of using these materials for paper tray production

Environmentally sustainable: By effective recycling and reuse, the consumption of natural resources is reduced. And paper trays have a smaller impact on the environment and are in line with the concept of sustainable development.

Degradable: Paper trays are mainly made of paper pulp. Once discarded or disposed of, paper pallets can decompose naturally, reducing the negative impact on the environment.

Lightweight: Paper trays are relatively light, which reduces transportation costs and energy consumption. Also, lightweight trays are easier to handle and stack, improving productivity.

Customizability: Paper trays can be designed and made to meet specific size, shape and structure requirements to suit different packaging needs.

Good protection performance: Good cushioning and protection performance can effectively protect the product from damage by external factors such as vibration, impact and extrusion.

How to make paper trays by using these raw materials?

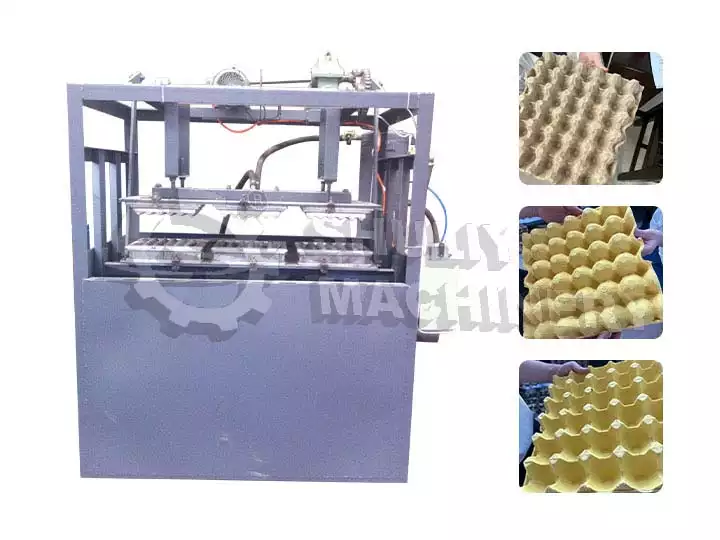

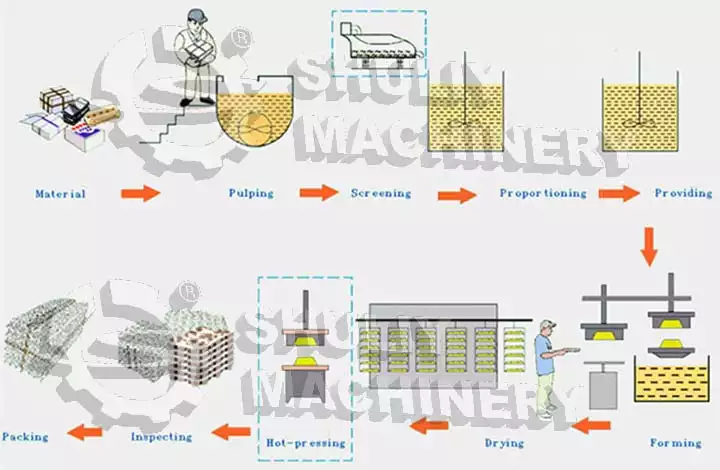

This requires our egg tray machine to help us with the production of quality egg trays. The general process is as follows:

Pulping —- Forming —- Drying —- Hot pressing —- Packing

Among them, the pulping machine is needed for pulping, and the paper tray machine is needed for forming, which is the most important part. The rest can be customized according to your needs.