How do you manufacture egg trays?

Egg trays are an important part of packaging and transportation and are often made from recycled paper. The manufacturing process involves several key steps that contribute to environmentally friendly and efficient production. Now let’s take a deep look at the egg tray production process.

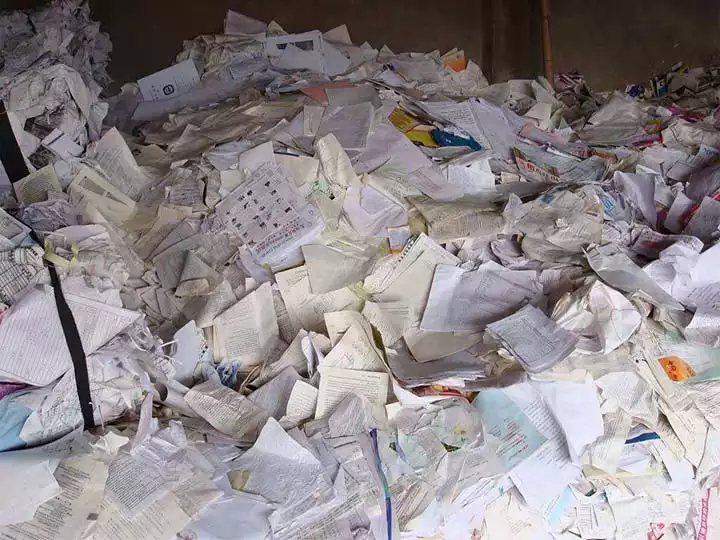

Step 1: Raw material preparation for egg trays

The process begins with the collection and sorting of waste paper, including newspaper, cardboard and other paper products. The collected paper is then shredded and soaked in water to form a pulp mixture. This pulp is the main material used to make egg trays.

Step 2: Pulp processing

The pulp is crushed and mixed with water to form a consistent mixture. Any impurities or unwanted materials are removed at this stage to ensure the quality of the final product. The water content and consistency of the mixture is adjusted to achieve the desired result.

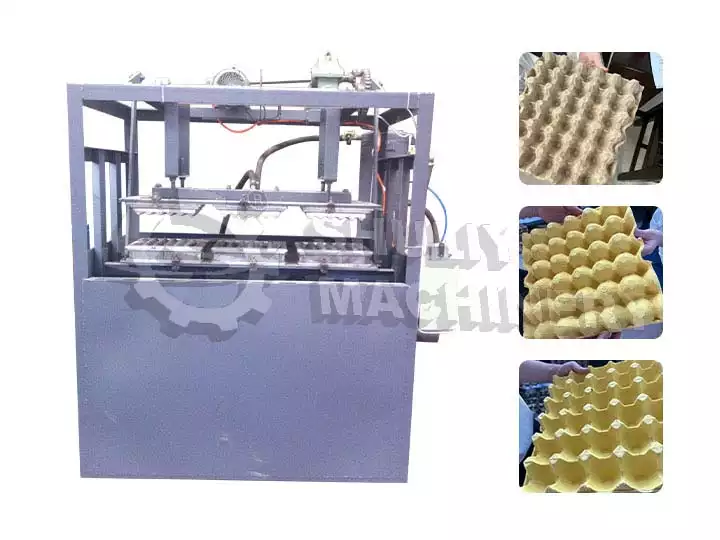

Step 3: Molding process

The molding process is a crucial step in egg tray manufacturing. The pulp mixture is poured into specially designed molds that resemble the shape of an egg cup. Excess water is drained and the pulp is pressed against the walls of the mold to form the desired shape. This process needs the egg tray machine.

Step 4: Drying

After molding, the newly formed egg trays are still wet. They are transferred to a drying chamber or conveyor belt for thorough drying. The drying process can involve natural air drying or the use of specialized drying equipment, depending on the scale of production and available resources.

Step 5: Stacking

Once the egg trays are completely dry, the trays are then stacked and bundled for packaging and transportation. The trimmed scraps produced at this stage can be recycled to produce more paper pulp.