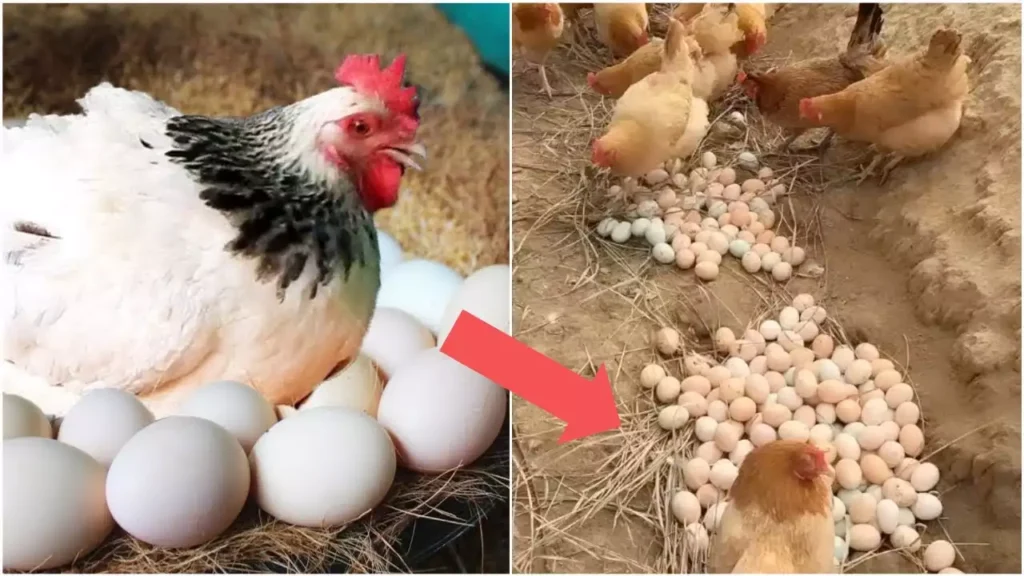

Invest in egg paper tray making machine for Nigerian egg packing and transportation

This customer operates a large chicken farm in Nigeria, supplying eggs to local supermarkets, retailers and wholesale markets. With the continuous growth of the business, the customer needs a more stable and economical way of egg packaging to ensure that the eggs are well-protected during transportation, reduce breakage and improve supply efficiency. Thus, our egg paper tray making machine is his best choice.

Problems: high egg packaging costs and unstable supply

In the past, the customer had been purchasing egg trays from an external supplier. However, as the market demand increased, he realized that there were the following problems with outsourcing egg trays:

- High cost: the cost of purchasing egg trays over a long period was increasing, affecting overall profitability.

- Unstable supply: sometimes there is a shortage of egg trays in the market, which leads to egg packaging problems and affects the sales plan.

- Unstable quality: some of the egg trays are of poor quality and cannot protect the eggs effectively, resulting in damage during transportation.

In order to reduce cost and ensure stable supply, customers decided to produce their own egg trays in order to realize the autonomy of egg packaging.

Why choose our egg paper tray making machine?

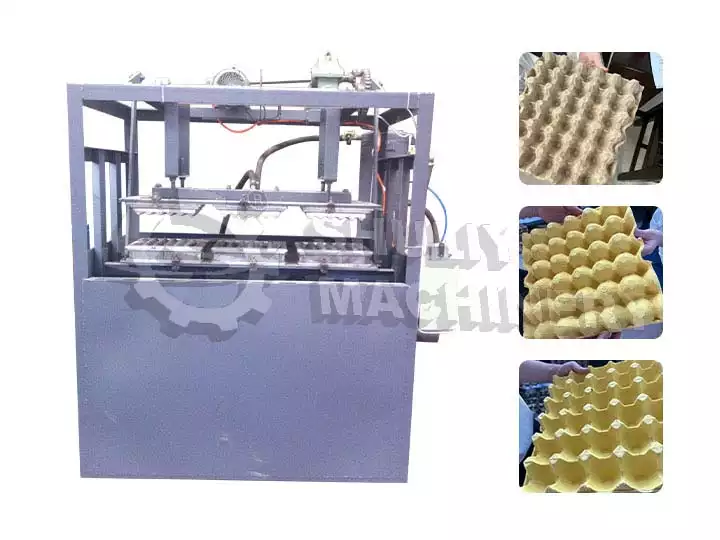

After comparing several suppliers, the customer finally chose our 3-4 egg tray machine for the following main reasons:

- Production capacity matches the demand: model 3-4 Egg Tray Machine can produce 2,000-2,500 pieces of egg trays per hour, which can meet the customer’s daily egg packaging demand.

- Use waste paper as raw material to reduce cost: customers can utilize local waste paper for egg tray production, saving purchasing costs and meeting the environmental protection requirement at the same time.

- Automated production to improve efficiency: the equipment is highly automated and easy to operate, greatly reducing labor costs.

- Stable quality and egg protection: the paper trays produced are sturdy and durable, which can effectively reduce the breakage rate of eggs during transportation.

From equipment procurement to successful production

After examining the market, the customer contacted us and visited our egg tray factory to get a detailed understanding of the production process and product quality of the egg paper tray making machine. Finally, he decided to order an egg tray production line, including 3-4 egg tray machine and pulping machine.

After the production of the equipment was completed, we conducted a comprehensive test on the machine and arranged transportation to Nigeria. After the customer received the equipment, our technical team provided remote guidance to help him install and commission the equipment smoothly.

After the trial run, this egg paper tray making machine was running well and officially put into operation.

Currently, the customer not only provides egg trays for its own chicken farms, but has also begun to supply egg trays to other local farmers, further expanding its business scope and adding source of income.